Product Description

CHPARASOL Aluminium oxide is gas phase method nano powder with positive electricity. All kinds of powder can be used in painting. The powder is well suitable for friction construction method due to its positive electricity. Under certain circumstances, It can make powder that cannot be triboelectrified into triboelectricity. After adding, it can reduce the electrostatic charge that hinders the flow and assist the powder deposition during the construction process.

The application feature in the powder painting:

Adding rare gas phase alumina(0.1% ~ 0.3%)into powder painting can be get remarkable effect.

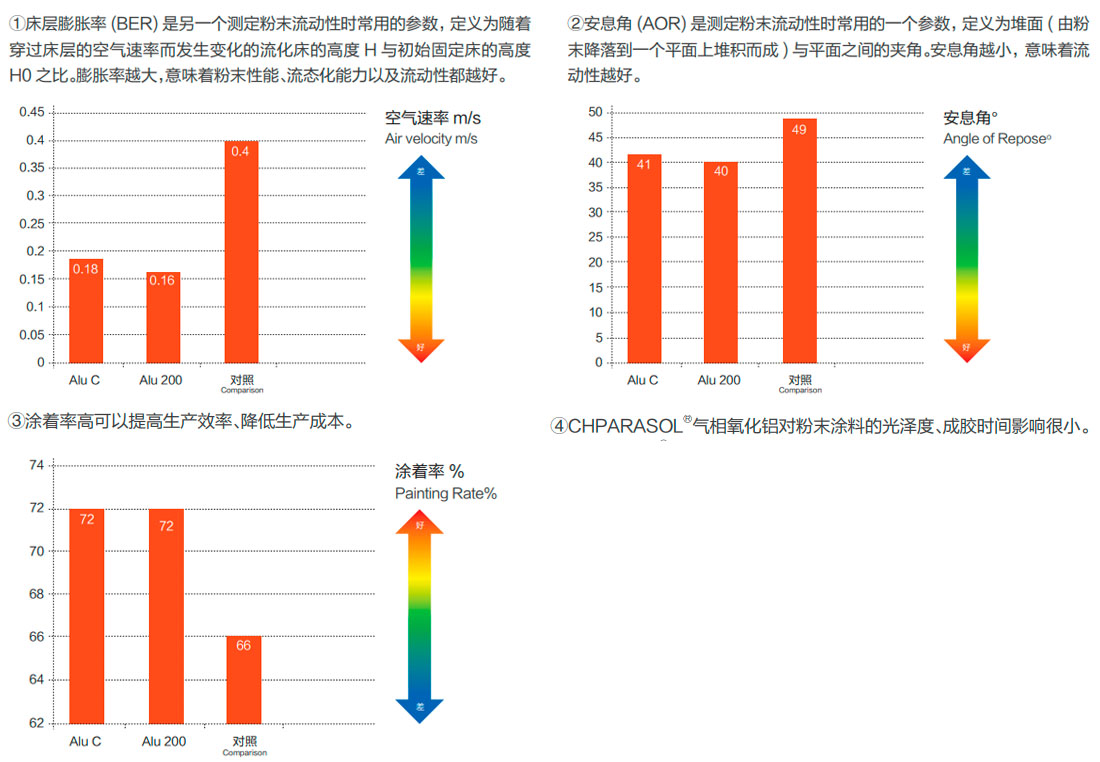

Improve free flow performance

Enhance storage stability

Reduce moisture absorption

Improve edge coating effect

Improve the positive chargeability of friction powder

The above-mentioned excellent performance benefits from the nano-scale particle size and dispersion obtained during the production process, as well as the charge on the surface of the particles themselves.

How to use: (to ensure that the desired effect is achieved, it is recommended to use the following methods)

Adding methods are:

In the powder painting production process, the fine crushing and sieving process after pre-mixing with the extruded sheet has the best effect;At the entrance of the rotary sieve, the material is fed into the powder at a uniform speed for mixing and sieving whose effect is better;The effect is acceptable after dry powder blending with the finished powder(The depth of mixing and the degree of opening of the powder agglomerates determine the relative performance of the finished powder)

Notes when adding:

when transporting the powder material, you should remove static electricity in time to avoid causing personal injury or generating flame igniting surrounding combustibles;When useing the powder, it's easy to cause dust phenomenon beause of its light density,and the space environment or facilities need to have induced wind or dust removal facilities to reduce or avoid the risk of personnel occupational hazards.

The product packaging is three-layer kraft paper packaging with certain waterproof and moisture-proof function, and after unpacking, you need to use it up as soon as possible or take waterproof, moisture-proof, and anti-pollution measures in time.

Package description:

Bag type: kraft paper bag, fluffy bag, 10kg/bag

Tray type: 2 bags/layer, 8 layers/pallet, wrapped with stretch film

20-foot container: 10 pallets/container, 160kg/pallet, 1600kg/container

40-foot container: 20 pallets/container, 160kg/pallet, 3200kg/container

Note: Waterproof and moisture-proof during transportation and storage.

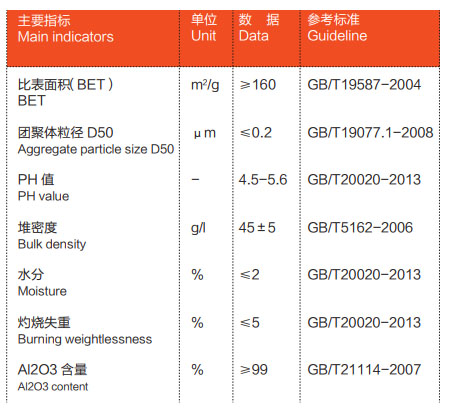

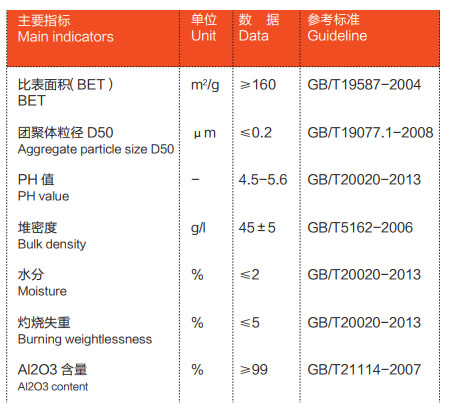

Characterization Parameters

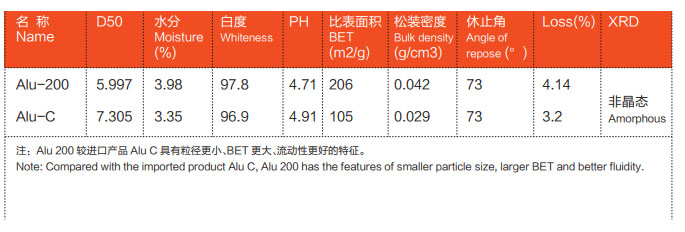

Application Advantage

+86-13922504134

+86-13922504134

E-mail

E-mail