Summarize MCB

1.Description:

When the colophony in powder system flows during the solidifying process at high temperature, its surfacetension is rather great. During this process, MCB shrinks and enhance its surface tension. The effect ofshrinking influences the wrinkle formation resulted from the surface fluidity during the process of filmformation. In this system, the hammer profiling is available within the silver crowded and the pattern, stripeorcrack is available with the pigment outer.

2.Typical physical data

Appearance: white powder

Volatilization: <1%

3.Suggested formula

| Wrinkle | Hammer profiling |

| Epoxy resin 280 | Epoxy resin 420 |

| Polyester 280 | Polyester 420 |

| MCB 1-3 | BaSO4 200 |

| Titanic oxide 150 | MCB 1-1.5 |

| BaSO4 100 | Sliver 10 |

| CaCO3 (light mass) 180 | Pigment // |

4.Characteristics

1. The size of texture decreases along with increase of addition quality of MCB. The aperture will appear if thequality of MCB is too small.

2. If you need strong third dimension of goffer, there are three choices, a: choose epoxy resin or polyester intenerating at a high temperature in order to reduce the gelling time, b: increase the colophony and use BaSO4as the filling, c: addition 0.1% solidifier of low temperature.

3. It's only covered from Silver when preparing hammer profiling powder. If revealed at the end ,it shouldincrease the amount of silver powder or choose silver powder with strong Hiding Power; Silver Powder directlydetermines the quality of the metal coating flu appearance, the poor quality of the silver powder will makethelayout gray or level flu between the end and the surface not strong; with addition of 0.1%T-988 it can makethehammer profiling more well-regulated to effectively prevent leakage at the end, and more stable.

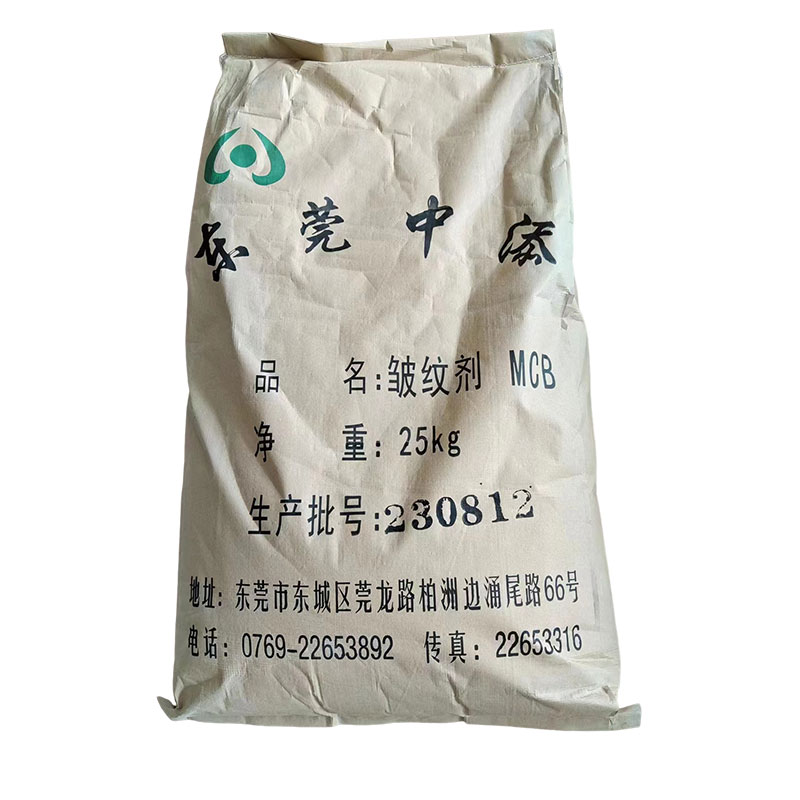

5.Packaging and storage

Polyethylene lining, net weight 25KG caveat; stored in a cool and dry placetoavoidmoisture absorption.In the < 30 ℃ is valid for two years at room temperature

.jpg)

.jpg)

.jpg)

+86-13922504134

+86-13922504134

E-mail

E-mail